It’s been a while since I’ve been able to get back to bicycle projects. Moving, setting up the new apartment and then beer brewing season have a way of eating up time! But this weekend, thanks to a jammin’ stitch-and-bitch session, I was able to get the portable radiobox working. It’s not complete, yet, but I’m at least able to test it out!

I had to first paint the bottom coat. I’m using marine paint, which does an excellent job making concrete void (cardboard tube) water-resistant:

It does off-gas quite a bit as it dries, however. I ended up moving it into the garage to let it dry; it took about a week for the first coat to dry out. I sanded that, applied another layer, let that dry for several days and then painted a topcoat. I applied two layers of topcoat, let that dry and then the shell was complete:

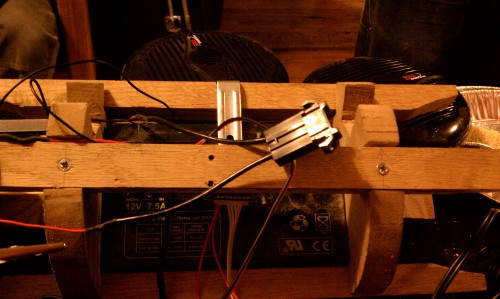

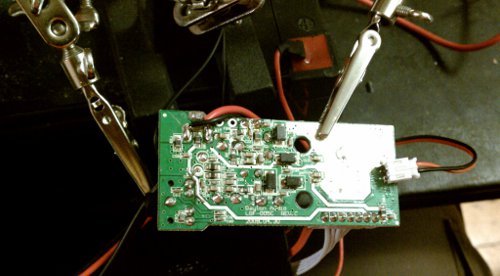

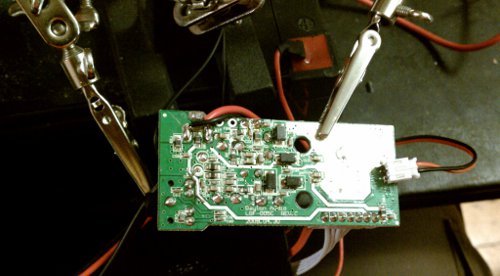

Now I could get into the guts of wiring it all up! The wiring diagram is classified but here’s some electronics nerd porn:

I tried to limit the number of holes in the case and cut them carefully. Here’s the hole where the on/off switch mounts, and the battery charging port in place:

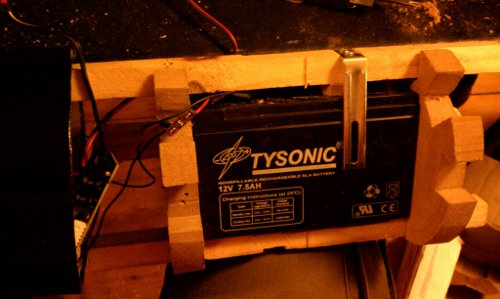

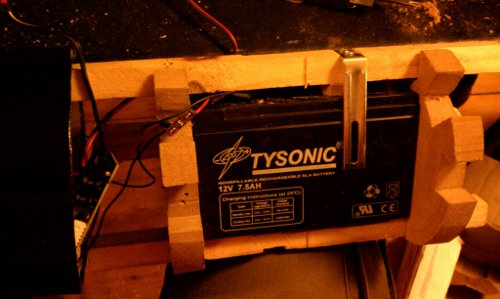

The battery fit perfectly and I found an angle bracket that worked to hold it in place:

A few hours of swearing, jamming things inside and cutting parts off the internal frame, and I had the finished prototype!

And here it is, mounted on the bike rack on my winter commuter:

There’s still some work to do. I’ve got to attach external RCA audio jacks instead of using a wire that runs out of it, otherwise I have to keep attaching and removing the audio cable from the bicycle frame every time I take the radio off the rack. The internal wiring needs some cleanup while I’m in there. I need to touch up some of the scratches I made when assembling it, make some minor adjustments to the internal frame which is a few millimeters too long, and add a power LED. While the parts are on order, though, I’m still going to enjoy using it!

Comments(2)

Comments(2)