Radiobox prototype, beta version, finished

I’ve resolved a few problems with the initial design.

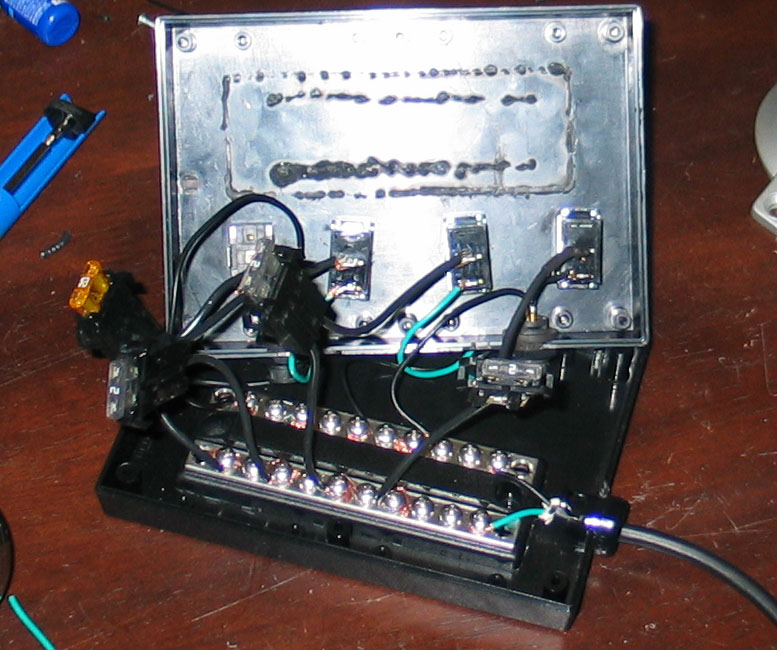

1. Added an LED power indicator light.

2. Added an ATO fuse holder instead of soldering the fuse directly to the power wires. This allows for fuse removal and replacement:

3. Added an external 1/4″ stereo jack, so that the audio cable between the amp and the iPod isn’t permanently attached to the amp. This simplifies removing the amp from the bicycle rack and makes it a modular unit without permanently attached cables dangling from it:

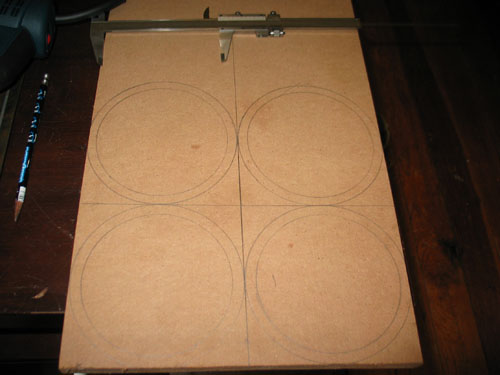

4. Replaced an internal MDF brace with a wooden cross-brace. This leaves more room for cables internally and reduces the chance that a cable will get snagged during disassembly. Sometimes it’s okay to use the wrong tools for the job — that’s a flat head screwdriver being used as a chisel:

Completed brace:

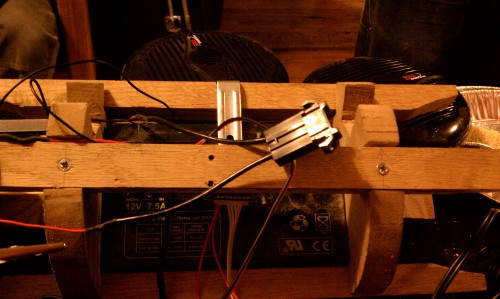

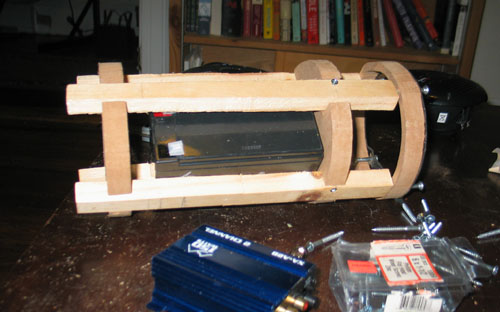

5. Replaced the jury-rigged internal battery braces with wooden block bracing. The wooden block bracing is more robust and simpler than the old metal bracket, which bent during use due to vibration:

6. Replaced the internal pine bracing with oak bracing. The oak bracing is much stronger, and speakers can be directly screwed into the ends of the oak bracing. MDF is not structurally strong enough to stand up to repeated disassembly and reassembly.

This is the end point for this version of the portable radiobox. The next revision – a totally different unit – will have several improvements, which are under wraps for now!

Comments(2)

Comments(2)