Conjunction junction

Well, after getting an arbor for a joint jigger, learning how to use a hole saw, and wheedling some welding this ship is finally RIDEABLE! I used two 3/8″ steel rods to brace the seatpost against the rear dropouts. Check it:

A close-up of the seatpost:

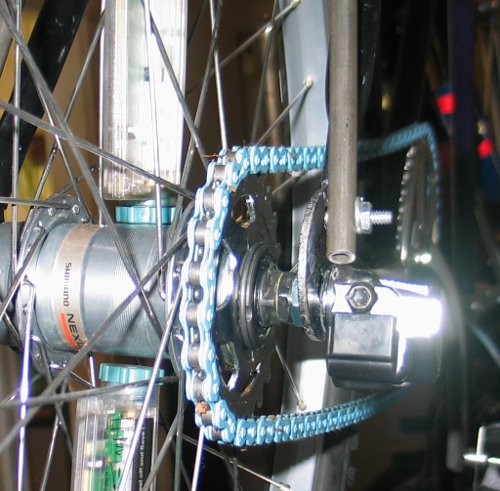

And another of the axle, with temporary bolts installed; those have since been replaced with stronger steel bolts:

The next challenge is to figure out how to mount the radiobox parts. There’s still about 8′ of 3/8″ steel rod left, so I’m planning on bending it into a rear rack that I can hang the amplifier from. I’m not sure where to put the subwoofer and the enclosure yet, but it might fit underneath the front part of the frame. We’ll see.

In the meantime, I’ve set up and tested the radiobox:

It’s a relatively simple device. An iPeed with a split output feeds the amp:

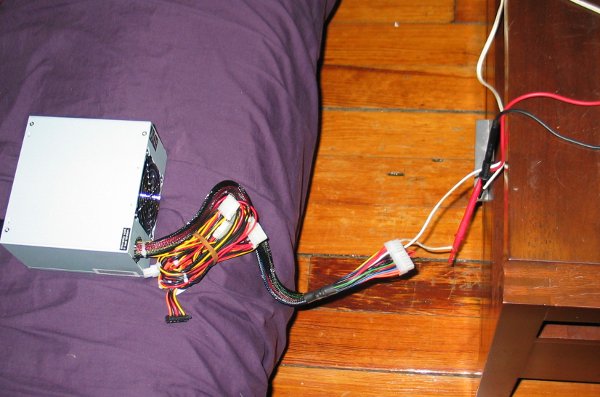

And I’ve rigged up a computer power supply to provide +12VDC:

which runs through a multimeter so that I can monitor the load and size the batteries properly. The radiobox parts all work, which is great, and it draws around 4 amps at a significant volume, so I’ll be getting a pretty hefty battery to keep this thing making noise for 4-6 hours at a stretch.

Comments(30)

Comments(30)